Exploring the Differences Between Industrial Vacuum Equipment and Laboratory-Grade Tools

Industrial vacuum equipment and laboratory-grade tools both serve essential roles in various fields, but their design, capabilities, and applications differ significantly. Understanding these differences is crucial for selecting the right vacuum solutions tailored to specific needs. This article delves into the unique characteristics of industrial vacuum equipment, contrasting them with lab-grade tools to provide a comprehensive overview.

Key Characteristics of Industrial Vacuum Equipment

Designed for Heavy-Duty Applications

Industrial vacuum equipment is engineered to handle large-scale and demanding operations. These machines are built to endure continuous use in tough environments such as manufacturing plants, construction sites, and waste management facilities. Their robust construction ensures durability and long service life, often under harsh conditions.

The ability to manage large volumes of dust, debris, and liquids makes industrial vacuum equipment indispensable in many sectors. They are designed to handle contaminants that would quickly clog or damage less rugged vacuum systems.

High Capacity and Power

One of the defining features of industrial vacuum equipment is its high suction power and capacity. These units can generate substantial vacuum pressure and airflow rates, enabling them to clean or extract materials efficiently over large areas or from deep containers.

This high capacity is essential for applications like removing heavy metal shavings in machine shops or cleaning extensive floor spaces in warehouses, where lab-grade tools would fall short in performance.

Distinct Features of Laboratory-Grade Vacuum Tools

Precision and Sensitivity

Laboratory-grade vacuum tools prioritize precision and sensitivity over sheer power. These tools are designed for delicate operations such as sample preparation, filtration, or controlled environment experiments where contamination control is critical.

The vacuum levels achieved by lab-grade tools are often finer, allowing for precise manipulation of gases or liquids under specific conditions, which is vital for scientific accuracy.

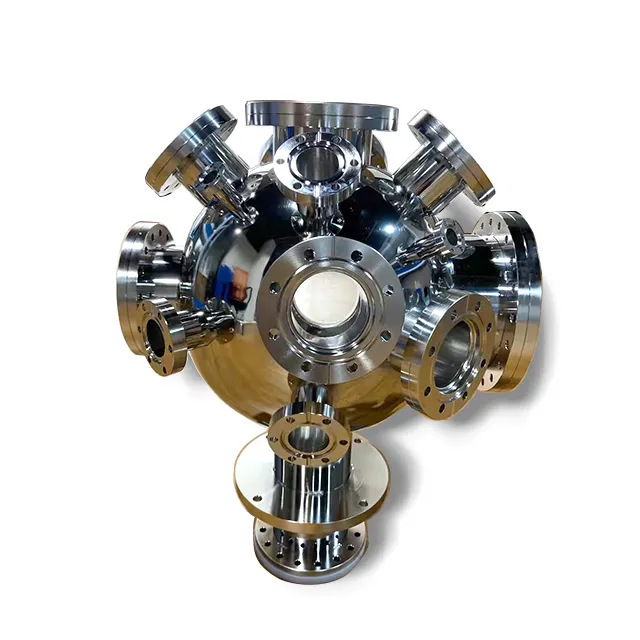

Compact and Specialized Designs

Lab-grade vacuum equipment tends to be smaller and more specialized. They often incorporate features that enable easy integration with other laboratory apparatus and instruments.

The compact design supports a controlled environment, minimizing external interference and ensuring reproducible results. Unlike industrial vacuum equipment, these tools focus more on accuracy than handling bulk materials.

Application Environments of Industrial Vacuum Equipment

Manufacturing and Construction

Industrial vacuum equipment plays a vital role in manufacturing and construction industries. In these settings, they are used for tasks such as cleaning debris, collecting metal dust, and removing liquids from work areas. Their rugged design allows them to withstand rough handling and exposure to dust, moisture, and abrasive materials.

These vacuums contribute to workplace safety by controlling airborne contaminants and preventing accumulation of hazardous materials.

Waste Management and Environmental Services

In waste management, industrial vacuum equipment facilitates the efficient collection and disposal of waste materials. They are instrumental in hazardous waste cleanup, sewage systems maintenance, and spill response.

Their ability to handle large volumes and a variety of substances makes them suitable for environmental remediation tasks, where lab-grade vacuum tools are insufficient.

Laboratory-Grade Vacuum Tools in Scientific Research

Controlled Atmosphere and Sample Handling

Lab-grade vacuum tools are essential for experiments requiring controlled atmospheres or specific vacuum conditions. They allow scientists to manipulate gases or liquids without contamination or loss.

Applications include filtration, degassing, and vacuum drying of samples, where the equipment’s precision directly impacts experimental outcomes.

Integration with Analytical Instruments

These vacuum tools often integrate seamlessly with analytical instruments such as spectrometers or chromatographs. This integration ensures that vacuum conditions remain stable during analysis, enhancing the reliability of results.

The compactness and precision of lab-grade tools support delicate measurements that are not achievable with industrial vacuum equipment.

Material and Construction Differences

Durability and Materials Used in Industrial Vacuum Equipment

Industrial vacuum equipment is typically constructed from heavy-duty metals and reinforced plastics designed to resist wear, corrosion, and impact. Components are often sealed to protect against dust and moisture ingress.

This construction supports continuous, intensive use in environments where damage is a constant risk.

Precision Engineering in Laboratory Tools

Laboratory-grade vacuum tools are crafted with precision-engineered components to maintain strict vacuum standards. Materials used prioritize chemical resistance and minimal outgassing, preserving sample integrity.

The engineering focus is on maintaining a clean, contamination-free environment rather than withstanding physical abuse.

Maintenance and Operational Considerations

Industrial Vacuum Equipment Maintenance

Maintaining industrial vacuum equipment involves regular inspection and replacement of filters, seals, and hoses to ensure peak performance. The demanding environments require durable parts and robust maintenance schedules.

Proper upkeep prevents downtime and extends the operational lifespan of the equipment.

Care and Calibration of Laboratory Vacuum Tools

Laboratory-grade vacuum tools require careful calibration and routine cleaning to maintain precision. Regular checks ensure that vacuum levels remain consistent and that contamination risks are minimized.

Given their specialized nature, these tools often need expert handling and service.

Advantages of Industrial Vacuum Equipment in Heavy-Duty Applications

Enhanced Efficiency in Large-Scale Operations

Industrial vacuum equipment significantly improves efficiency by handling large-scale cleaning and extraction tasks swiftly. Their power and capacity reduce labor and time requirements compared to manual or less powerful alternatives.

This advantage translates into cost savings and improved productivity.

Safety and Environmental Benefits

By effectively capturing hazardous dust and liquids, industrial vacuum equipment enhances workplace safety and environmental protection. These machines help comply with regulatory standards and reduce health risks for workers.

Their role in mitigating contamination and pollution is critical in many industrial sectors.

Frequently Asked Questions

What distinguishes industrial vacuum equipment from laboratory vacuum tools?

Industrial vacuum equipment is designed for heavy-duty, high-capacity tasks in harsh environments, focusing on durability and power. Laboratory vacuum tools emphasize precision, sensitivity, and integration with scientific instruments.

Can industrial vacuum equipment be used in laboratory settings?

Generally, industrial vacuum equipment is too large and powerful for delicate laboratory tasks. Laboratory settings require specialized tools that offer finer control and maintain contamination-free environments.

How often should industrial vacuum equipment be maintained?

Maintenance frequency depends on usage and operating conditions but generally includes regular filter replacements and inspections to ensure consistent performance and longevity.

Are there customization options available for industrial vacuum equipment?

Yes, many manufacturers offer customization to tailor industrial vacuum equipment to specific application needs, enhancing efficiency and effectiveness.

Table of Contents

- Exploring the Differences Between Industrial Vacuum Equipment and Laboratory-Grade Tools

- Key Characteristics of Industrial Vacuum Equipment

- Distinct Features of Laboratory-Grade Vacuum Tools

- Application Environments of Industrial Vacuum Equipment

- Laboratory-Grade Vacuum Tools in Scientific Research

- Material and Construction Differences

- Maintenance and Operational Considerations

- Advantages of Industrial Vacuum Equipment in Heavy-Duty Applications

- Frequently Asked Questions