Comprendre le rôle essentiel des vannes à clapet dans les applications sous vide modernes

Vannes d'isolation à vide représentent une technologie fondamentale dans les systèmes modernes de vide, servant de composants essentiels qui influencent considérablement la performance et la fiabilité globales du système. Ces vannes spécialisées ont révolutionné la manière dont les industries maintiennent et contrôlent les environnements sous vide, de la fabrication de semiconducteurs aux installations de recherche scientifique. Leur conception et leurs caractéristiques opérationnelles uniques les rendent indispensables pour assurer un contrôle précis du vide et maintenir l'intégrité du système.

La mise en œuvre des vannes à vide de type gate est devenue de plus en plus sophistiquée, car les procédés industriels exigent une précision et une efficacité accrues. Ces vannes servent de points d'isolation critiques au sein des systèmes sous vide, permettant aux opérateurs de maintenir des conditions de pression optimales tout en garantissant un fonctionnement fluide des équipements connectés. Leur capacité à assurer une étanchéité fiable et une activation rapide en fait le choix privilégié pour de nombreuses applications de haute technologie.

Composants essentiels et caractéristiques de conception des vannes à clapet pour vide

Éléments mécaniques essentiels

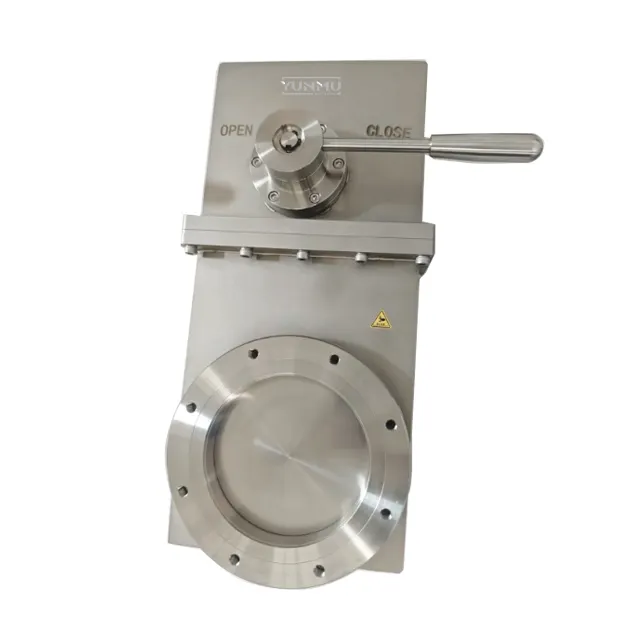

La conception fondamentale des vannes à clapet pour vide intègre plusieurs composants clés qui fonctionnent en synergie pour garantir des performances optimales. Le clapet, généralement fabriqué en acier inoxydable de haute qualité, sert d'élément principal d'étanchéité. Ce clapet se déplace perpendiculairement au trajet du fluide, créant une barrière efficace lorsqu'il est fermé. Le corps de la vanne abrite des guides et supports de précision conçus pour assurer un mouvement fluide du clapet tout en maintenant un alignement correct durant le fonctionnement.

Les composants annexes comprennent des joints spécialisés, souvent réalisés en matériaux élastomères ou en métal selon les exigences de l'application. Ces joints doivent conserver leur intégrité sous diverses conditions de pression tout en empêchant toute contamination potentielle de l'environnement sous vide. Le mécanisme d'actionnement, qu'il soit manuel, pneumatique ou électronique, fournit la force nécessaire pour un positionnement précis du clapet.

Technologie de scellement avancée

Les vannes d'isolation modernes utilisent des mécanismes d'étanchéité sophistiqués qui représentent des progrès significatifs dans la technologie du vide. Le système d'étanchéité se compose généralement de joints primaires et secondaires fonctionnant en conjonction pour assurer une efficacité maximale. Ces joints sont conçus pour conserver leurs propriétés même sous des variations extrêmes de température et lors de cycles répétés.

Les ingénieurs ont développé des solutions innovantes d'étanchéité intégrant des matériaux spécialisés et des traitements de surface afin d'améliorer la longévité et les performances des joints. Ces avancées ont permis d'améliorer l'étanchéité et d'allonger les intervalles de maintenance, contribuant ainsi à la fiabilité globale du système et à son efficacité économique.

Avantages opérationnels dans les systèmes sous vide

Caractéristiques de flux améliorées

Les vannes à vide offrent de meilleures caractéristiques d'écoulement par rapport aux conceptions traditionnelles de vannes. Leur conception avec orifice droit minimise la résistance à l'écoulement à l'état ouvert, permettant une conductance optimale et réduisant les temps de pompage. Cette efficacité est particulièrement cruciale dans les processus à haut débit où des changements rapides de pression sont requis.

Le trajet d'écoulement rationalisé réduit également les turbulences et la génération potentielle de particules, ce qui rend les vannes à vide idéales pour les environnements de traitement propres. Leur conception leur permet de gérer de fortes charges gazeuses tout en maintenant des performances constantes sur diverses plages de pression.

Contrôle de Précision et Fiabilité

La mise en œuvre de vannes à vide assure un contrôle exceptionnel des environnements sous vide. Leur nature rapide permet une isolation rapide des sections du système lorsque nécessaire, tandis que leur construction robuste garantit un fonctionnement fiable sur de longues périodes. Ce contrôle précis est essentiel pour maintenir la stabilité du processus et protéger les équipements sensibles.

Les systèmes de contrôle modernes intégrés aux vannes pneumatiques offrent des capacités de surveillance et de réglage en temps réel, permettant aux opérateurs d'optimiser les performances du système selon les exigences spécifiques de chaque application. La capacité de contrôler précisément les conditions sous vide contribue de manière significative à la qualité et à la constance des procédés.

Applications et incidence sur l'industrie

Excellence dans la fabrication des semiconducteurs

L'industrie des semiconducteurs dépend fortement des vannes pneumatiques pour maintenir des environnements de traitement ultra-propres. Ces vannes jouent un rôle crucial dans diverses étapes de la fabrication des puces, des procédés de dépôt aux opérations de gravure. Leur capacité à maintenir une haute intégrité sous vide tout en permettant un accès rapide pour la maintenance les rend indispensables dans les installations de fabrication modernes.

Le contrôle précis offert par les vannes à vide garantit des conditions de traitement constantes, influant directement sur les taux de rendement et la qualité des produits. Leur fiabilité dans le maintien d'environnements propres a grandement contribué à l'avancement de la technologie des semi-conducteurs et à la production de composants électroniques de plus en plus sophistiqués.

Applications en recherche et développement

Les installations de recherche scientifique utilisent des vannes à vide dans divers montages expérimentaux et instruments analytiques. Ces vannes permettent aux chercheurs de maintenir des conditions de vide précises, nécessaires pour des études avancées en physique, en science des matériaux et dans d'autres disciplines scientifiques. Leur polyvalence et leur fiabilité en font des composants essentiels dans les équipements de recherche sur mesure.

La mise en œuvre de vannes à vide dans les applications de recherche a permis des découvertes et innovations révolutionnaires. Leur capacité à maintenir des conditions de vide stables tout en permettant des modifications rapides des dispositifs expérimentaux a accéléré le rythme de la recherche et du développement scientifiques.

Stratégies d'entretien et d'optimisation

Protocoles de maintenance préventive

Le maintien des performances optimales des vannes à vide exige la mise en place de programmes complets de maintenance préventive. L'inspection régulière des surfaces d'étanchéité, des mécanismes d'actionnement et des systèmes de commande permet d'identifier les problèmes potentiels avant qu'ils n'affectent le fonctionnement du système. Un nettoyage et une lubrification appropriés des composants mobiles garantissent un fonctionnement fluide et une durée de vie prolongée de la vanne.

La documentation des activités de maintenance et des tendances de performance permet aux installations d'optimiser leurs plannings de maintenance et de prévoir les éventuels problèmes. Cette approche proactive de la maintenance des vannes réduit considérablement les temps d'arrêt et prolonge la durée de vie opérationnelle des vannes ainsi que celle de l'ensemble du système sous vide.

Techniques d'optimisation des performances

L'optimisation des performances des vannes à vide nécessite une attention particulière aux paramètres de fonctionnement et aux exigences du système. Un étalonnage régulier des systèmes de commande et la vérification de l'intégrité des joints garantissent des performances constantes. Des techniques de surveillance avancées, telles que la détection de fuites et le comptage des cycles, permettent de maintenir une efficacité optimale du système.

La mise en œuvre d'algorithmes de contrôle modernes et de systèmes d'automatisation peut améliorer davantage le fonctionnement des vannes, réduire les temps de réponse et accroître la fiabilité globale du système. Ces stratégies d'optimisation contribuent à une productivité accrue et à une diminution des coûts d'exploitation.

Questions fréquemment posées

Qu'est-ce qui distingue les vannes à vide des autres types de vannes ?

Les vannes à vide possèdent un design unique en ligne droite, avec une fermeture qui se déplace perpendiculairement au trajet du fluide, offrant ainsi une conductance supérieure et une résistance minimale au flux. Leurs mécanismes d'étanchéité spécialisés et leur construction robuste les rendent particulièrement adaptées pour maintenir une haute intégrité sous vide dans des applications exigeantes.

À quelle fréquence faut-il entretenir les vannes à vide à passage intégral ?

La fréquence d'entretien dépend de facteurs tels que les conditions de fonctionnement, le nombre de cycles et les exigences environnementales. Généralement, une inspection complète doit être effectuée tous les 6 à 12 mois, avec des vérifications plus fréquentes pour les applications critiques ou les opérations à haut nombre de cycles. Un suivi régulier des performances de la vanne peut aider à déterminer les intervalles d'entretien optimaux.

Quels sont les critères essentiels à prendre en compte lors du choix de vannes à vide à passage intégral ?

Lors du choix de vannes à vide à passage intégral, prenez en compte des facteurs tels que le niveau de vide requis, la plage de température de fonctionnement, la fréquence de cyclage et la compatibilité avec les fluides du procédé. D'autres considérations incluent le type d'actionnement, les exigences d'interface de commande et l'accessibilité pour la maintenance. Les besoins spécifiques de l'application doivent guider le choix des spécifications et caractéristiques appropriées de la vanne.

Table des Matières

- Comprendre le rôle essentiel des vannes à clapet dans les applications sous vide modernes

- Composants essentiels et caractéristiques de conception des vannes à clapet pour vide

- Avantages opérationnels dans les systèmes sous vide

- Applications et incidence sur l'industrie

- Stratégies d'entretien et d'optimisation

- Questions fréquemment posées