Understanding the Critical Role of Metal Bellows in Advanced Engineering

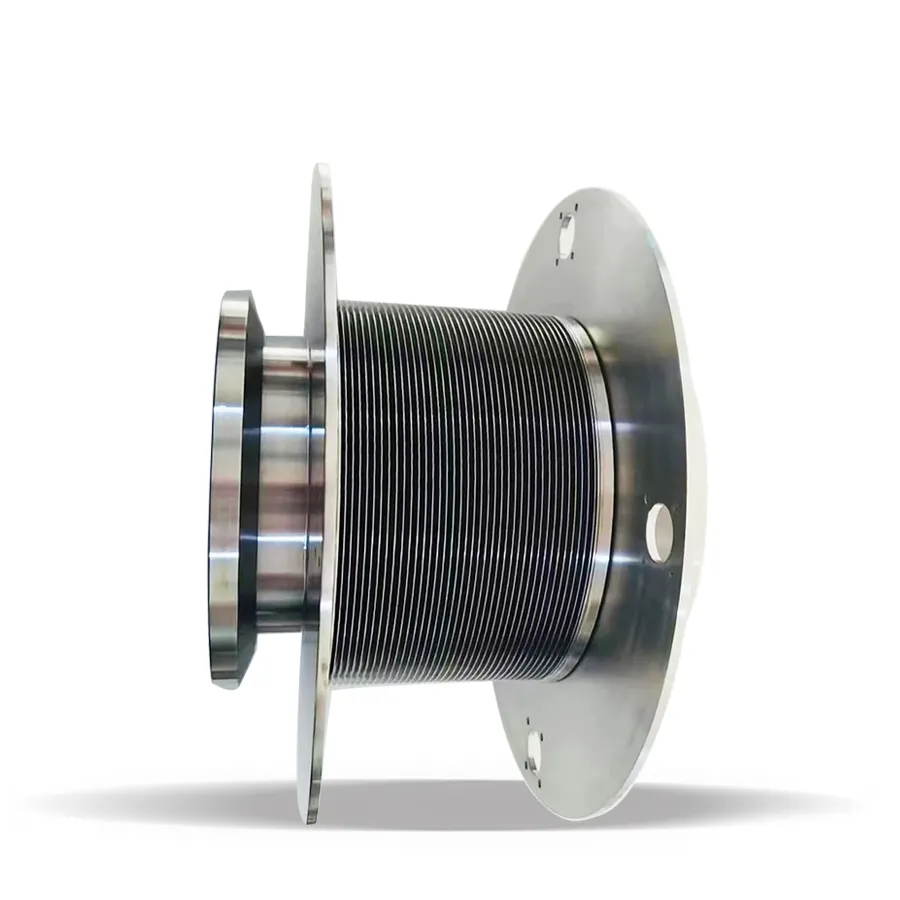

Metal bellows have emerged as indispensable components in modern vacuum and aerospace systems, serving as flexible yet robust solutions for various engineering challenges. These precision-engineered devices, featuring accordion-like structures made from specialized metal alloys, provide essential functions in some of the most demanding industrial and scientific applications. From maintaining vacuum seals in semiconductor manufacturing to enabling precise motion control in spacecraft, metal bellows represent a cornerstone technology in advanced engineering systems.

The versatility of metal bellows stems from their unique design, which combines flexibility with structural integrity. This combination allows them to handle extreme pressures, temperatures, and mechanical stresses while maintaining their functional properties. As we delve deeper into their applications and benefits, we'll discover why engineers consistently choose metal bellows for critical systems where failure is not an option.

Fundamental Applications in Vacuum Systems

Vacuum Sealing and Pressure Management

In vacuum systems, metal bellows serve as dynamic sealing elements that maintain system integrity while accommodating movement and thermal expansion. These components create hermetic seals that prevent leakage and contamination, crucial for maintaining ultra-high vacuum environments. The ability of metal bellows to flex and compress while maintaining a perfect seal makes them invaluable in vacuum chambers, mass spectrometers, and semiconductor processing equipment.

The pressure management capabilities of metal bellows extend beyond simple sealing. They can act as pressure compensators, absorbing system fluctuations and protecting sensitive equipment from damage. This is particularly important in systems where precise pressure control is essential for proper operation.

Motion Transfer in Vacuum Environments

One of the most significant advantages of metal bellows in vacuum systems is their ability to transfer motion from outside to inside a vacuum chamber without compromising the seal. This characteristic is crucial for applications requiring precise mechanical manipulation within vacuum environments, such as sample handling in electron microscopes or adjustment of optical components in vacuum-based measuring instruments.

Engineers often utilize metal bellows to create flexible couplings that can accommodate misalignment while maintaining vacuum integrity. This application is particularly valuable in large-scale scientific instruments where thermal expansion and mechanical stress must be managed without compromising system performance.

Aerospace Applications and Innovations

Propulsion System Components

In aerospace applications, metal bellows play a critical role in propulsion systems, serving as flexible connectors in fuel lines and exhaust systems. Their ability to handle extreme temperatures and pressures while accommodating thermal expansion and engine movement makes them essential components in modern aircraft and spacecraft engines.

The durability of metal bellows in harsh environments extends to their use in thrust vector control systems, where they help direct engine thrust for precise vehicle control. These applications require materials and designs that can withstand both cryogenic temperatures from fuel systems and extreme heat from engine operation.

Environmental Control Systems

Aircraft and spacecraft environmental control systems rely heavily on metal bellows for managing pressure differences and controlling air flow. These components help regulate cabin pressure, handle thermal expansion in air conditioning systems, and provide flexible connections in life support equipment.

The reliability of metal bellows in aerospace environmental control systems stems from their ability to perform consistently under varying atmospheric conditions and through numerous pressure cycles. This dependability is crucial for maintaining safe and comfortable conditions for crew and passengers.

Design Considerations and Material Selection

Material Properties and Performance

The selection of materials for metal bellows requires careful consideration of operating conditions and performance requirements. Common materials include stainless steel, Inconel, and specialized alloys chosen for their strength, corrosion resistance, and fatigue properties. Engineers must balance factors such as flexibility, pressure capability, and cycle life when specifying materials.

Advanced manufacturing techniques, including hydroforming and precision welding, ensure that metal bellows maintain their integrity under extreme conditions. The quality of materials and fabrication directly impacts the reliability and longevity of these critical components.

Engineering Specifications and Testing

Rigorous testing protocols validate the performance of metal bellows under simulated operating conditions. This includes cycle life testing, pressure testing, and environmental exposure trials to ensure components meet or exceed design specifications. Quality control measures throughout the manufacturing process help maintain consistency and reliability.

Engineers must consider factors such as spring rate, stroke length, and pressure capabilities when designing systems incorporating metal bellows. These specifications directly influence system performance and reliability, making proper selection and testing crucial for successful applications.

Future Trends and Developments

Advanced Manufacturing Technologies

The future of metal bellows manufacturing is being shaped by emerging technologies such as additive manufacturing and advanced materials science. These innovations promise to deliver components with enhanced performance characteristics and more precise control over material properties.

Integration of smart materials and sensors into metal bellows designs may enable real-time monitoring of component health and performance, leading to predictive maintenance capabilities and improved system reliability.

Emerging Applications and Markets

As technology advances, new applications for metal bellows continue to emerge in fields such as renewable energy, space exploration, and advanced manufacturing. The development of more efficient and capable components will drive innovation in these sectors.

The growing demand for reliable, high-performance components in emerging industries presents opportunities for metal bellows manufacturers to develop specialized solutions for new challenges.

Frequently Asked Questions

What makes metal bellows suitable for aerospace applications?

Metal bellows are ideal for aerospace applications due to their ability to withstand extreme temperatures, pressures, and mechanical stress while maintaining flexibility and seal integrity. They also offer excellent fatigue resistance and can accommodate thermal expansion and movement in complex systems.

How long do metal bellows typically last in vacuum systems?

The lifespan of metal bellows in vacuum systems depends on various factors including operating conditions, cycle frequency, and maintenance practices. With proper design and installation, high-quality metal bellows can last for millions of cycles, often exceeding 10 years of service in typical applications.

Can metal bellows be customized for specific applications?

Yes, metal bellows can be customized in terms of size, material selection, wall thickness, and convolution design to meet specific application requirements. Manufacturers work closely with engineers to develop solutions that optimize performance for particular operating conditions and system specifications.