- Overview

- Related Products

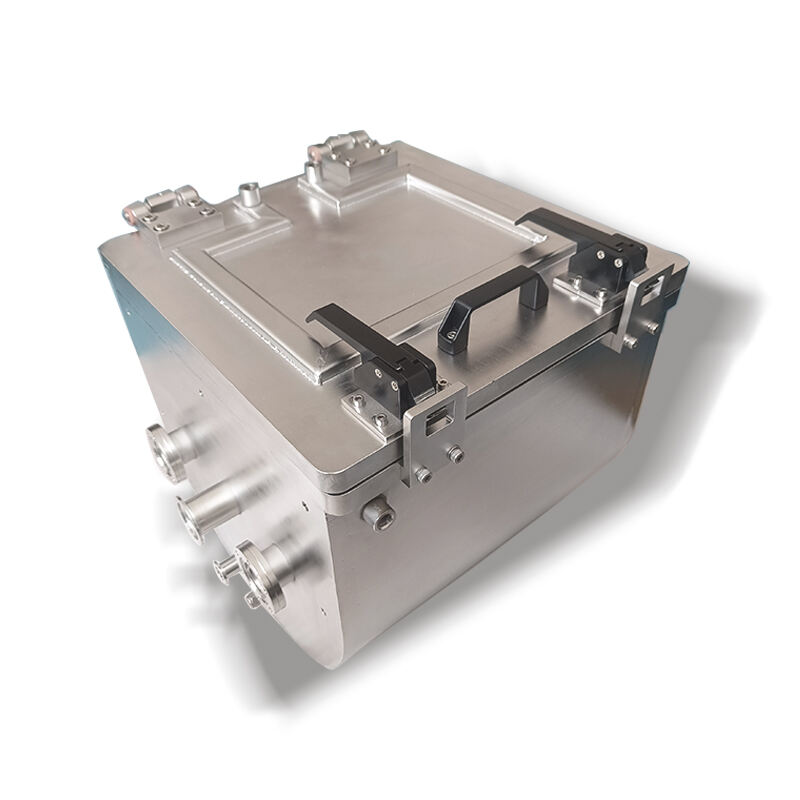

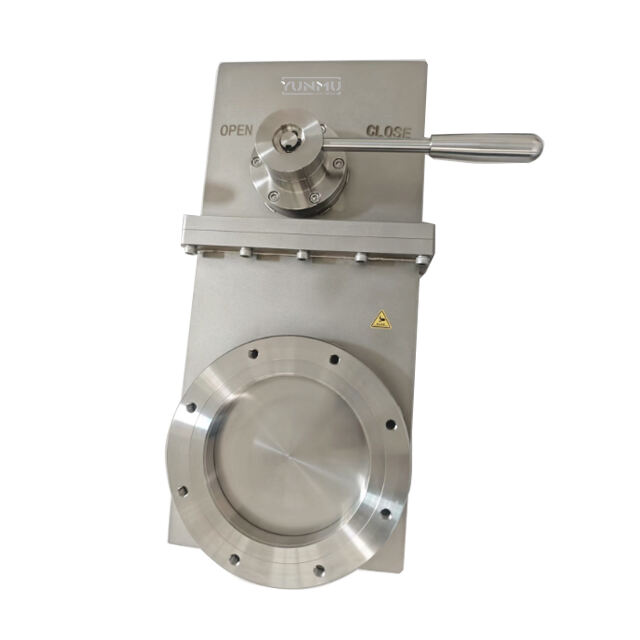

YM Technology specializes in designing and customizing box-shaped vacuum chambers, offering a robust cube design made from stainless steel. Available in three standard sizes—27L, 125L, and 1000L—these chambers are equipped with multiple ports for pump-down, vacuum gauges, and venting. The chamber features a convenient door design, and port quantity, size, type, and location can be customized to meet specific needs.

Surface treatment options include sanded or electrolytic polishing. Upon receiving your material and finish preferences, we provide a concept drawing and cost estimate. Our streamlined design process ensures quick adjustments, reducing communication and manufacturing time.

Applications and Customization:

Our box vacuum chambers are used globally across industries, government labs, corporate R&D, and academic institutions. They are suitable for medium to ultra-high vacuum (UHV) environments.

As a one-stop supplier, we support every stage—from design and manufacturing to installation and on-site service. We also produce large chambers over 2 meters in length for diverse applications, delivering high vacuum (HV) and UHV solutions tailored to your requirements.

Technical Parameters of Common Vacuum Chambers:

1. Material: 304 stainless steel, 316L stainless steel, or customer-specified materials.

2. Operating temperature range: -190°C to +1500°C (water cooling required for high temperatures).

3. Sealing method: Fluorine rubber "O" rings or oxygen-free copper metal seals.

Factory Testing Procedures:

1. Vacuum leak rate test: Standard leak rate: 1.3×10-11 Pa·L/s.

2. Water cooling pressure test: Standard test pressure: 11.6psi, 24hour leak-free test.

Surface Treatments:

- Electropolishing

- Sandblasting

- Acid cleaning

- Mirror polishing.

If you need to order our vacuum chambers, please contact our professional sales team and provide the following information:

1. Whether the product generates heat during use, the specific high and low temperatures, and whether water or liquid nitrogen cooling is required.

2. Any special material requirements. Common materials for vacuum chambers include carbon steel, aluminum, 304 stainless steel, and 316 stainless steel.

3. Connection methods, vacuum pumping methods, and the type of vacuum pump used.

4. Vacuum level requirements and whether protective or other gases need to be introduced after vacuuming.

For more information on custom vacuum chambers or other YM vacuum chamber components, contact us and share your drawings. We’re here to assist with your requirements!