- Overview

- Related Products

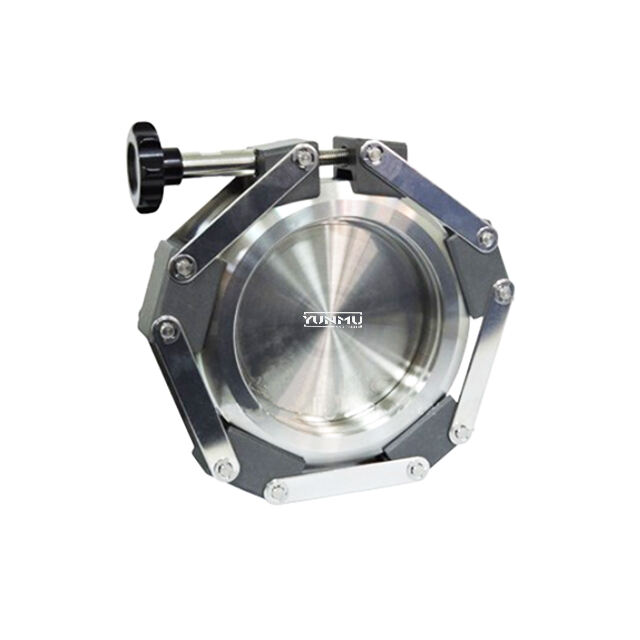

Polygon vacuum chambers are widely utilized in industrial coating and sputtering systems, designed for depositing functional and decorative thin films on various substrates. They are integral to systems such as DLC (Diamond-Like Coating), Arc Evaporation, and Magnetron Sputtering. These chambers are engineered with flexibility to meet diverse application needs.

Depending on specific requirements, polygon vacuum chambers can be customized into various shapes, including pentagon, hexagon, octagon, and more. Universities and R&D centers often require specialized vacuum chambers for experimental systems that combine flexibility, compact volumes, and low operating costs. YM Technology collaborates closely with customers to design and deliver the optimal vacuum chamber solution tailored to their unique needs.

Technical Parameters of Common Vacuum Chambers:

1. Material: 304 stainless steel, 316L stainless steel, or customer-specified materials.

2. Operating temperature range: -190°C to +1500°C (water cooling required for high temperatures).

3. Sealing method: Fluorine rubber "O" rings or oxygen-free copper metal seals.

Factory Testing Procedures:

1. Vacuum leak rate test: Standard leak rate: 1.3×10-11 Pa·L/s.

2. Water cooling pressure test: Standard test pressure: 11.6psi, 24hour leak-free test.

Surface Treatments:

- Electropolishing

- Sandblasting

- Acid cleaning

- Mirror polishing.

If you need to order our vacuum chambers, please contact our professional sales team and provide the following information:

1. Whether the product generates heat during use, the specific high and low temperatures, and whether water or liquid nitrogen cooling is required.

2. Any special material requirements. Common materials for vacuum chambers include carbon steel, aluminum, 304 stainless steel, and 316 stainless steel.

3. Connection methods, vacuum pumping methods, and the type of vacuum pump used.

4. Vacuum level requirements and whether protective or other gases need to be introduced after vacuuming.

For more information on custom vacuum chambers or other YM vacuum chamber components, contact us and share your drawings. We’re here to assist with your requirements!