Precision Flexibility in Vacuum Environments

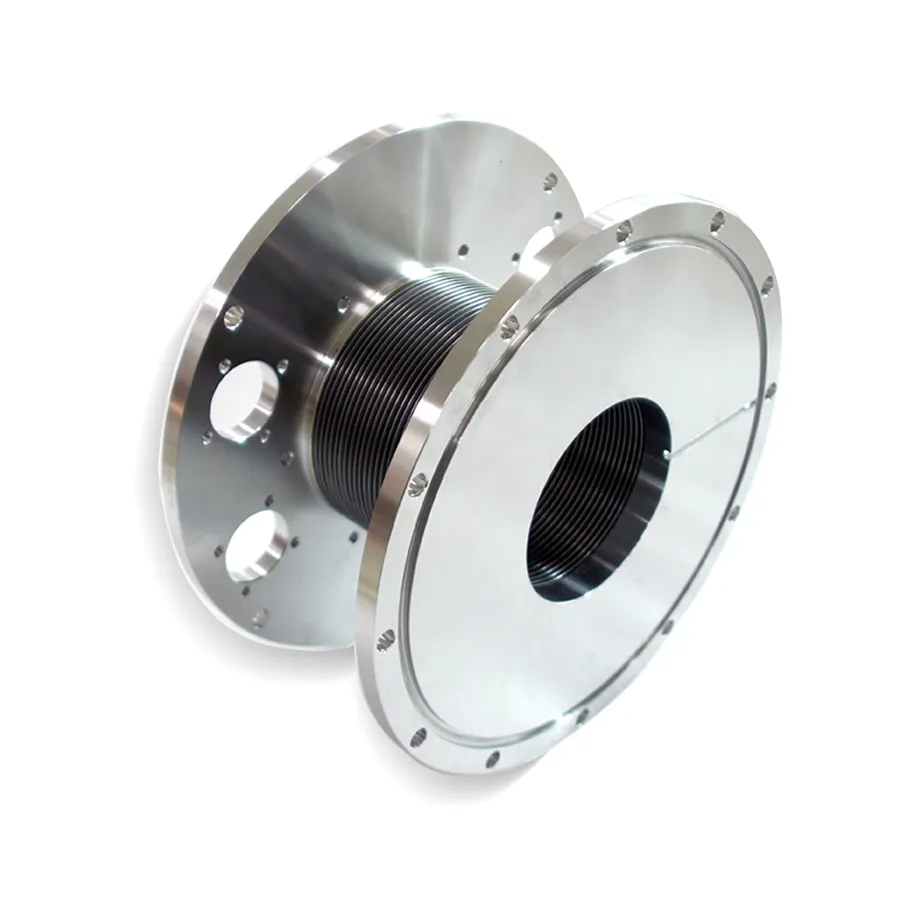

In advanced vacuum applications, precision and flexibility often define the efficiency and reliability of the system. One component that delivers both is the edge welded bellows. Engineered from thin metal diaphragms welded along their edges, edge welded bellows serve as a flexible, vacuum-tight solution for motion transfer, expansion absorption, and sealing in highly controlled environments.

The use of edge welded bellows has become integral in many high-tech industries such as semiconductor fabrication, aerospace engineering, and medical device manufacturing. Their unique ability to handle complex movements while maintaining ultra-high vacuum integrity makes them a preferred solution in systems requiring both motion and sealed isolation.

Versatility in Vacuum Transfer Systems

Linear and Angular Motion Compensation

Edge welded bellows are commonly used in vacuum transfer systems to compensate for both linear and angular movement. Whether it involves transporting wafers in semiconductor chambers or adjusting optics in laser systems, these bellows offer seamless mechanical motion while preserving system integrity. Their elasticity and low spring rate make them ideal for robotic arms and automated positioning systems.

Custom Motion Transmission in Isolation

Unlike conventional bellows, edge welded bellows are capable of withstanding multidirectional movements without compromising vacuum tightness. This feature allows them to be used as mechanical couplings between isolated chambers where precise movement and alignment are required. Such capabilities are essential in applications that demand zero leakage and dynamic range, such as ion beam chambers or electron microscopy systems.

Enabling High Vacuum and Ultra-High Vacuum Conditions

Superior Leak Tightness and Durability

One of the key reasons edge welded bellows are favored in vacuum applications is their exceptional leak tightness. The fusion welding of metal diaphragms ensures that no trapped volumes or joints exist within the structure that could compromise the vacuum. These bellows can be made from stainless steel, Inconel, Hastelloy, or other alloys suited for UHV environments, offering longevity and corrosion resistance under extreme conditions.

Compatibility with Cryogenic and Thermal Cycling

Edge welded bellows perform reliably even in cryogenic environments or in systems subject to intense thermal cycling. Their metal construction allows them to flex without fatigue over thousands of cycles, adapting to both shrinking and expansion without cracking or leaking. This is particularly important in scientific applications like particle accelerators and superconducting magnet systems.

Integration in Semiconductor Manufacturing

Vacuum Load Locks and Wafer Handlers

In the semiconductor industry, vacuum integrity is non-negotiable. Edge welded bellows are integrated into vacuum load locks and wafer handlers to enable movement between atmospheric and vacuum environments without compromising system pressure. Their design accommodates multiple axes of motion while reducing particle generation — a crucial factor in cleanroom operations.

Process Chambers and Substrate Transfers

Edge welded bellows are also used within process chambers where controlled material deposition or etching occurs. Their function includes transferring substrates or aligning components under vacuum. Because they offer low outgassing and can be cleaned to stringent standards, they ensure that no contaminants interfere with sensitive manufacturing processes.

Application in Analytical Instruments

Mass Spectrometers and Electron Microscopes

Edge welded bellows play a vital role in the operation of analytical instruments. In mass spectrometers and electron microscopes, where slight movements must occur within sealed vacuum chambers, bellows allow actuator motion while maintaining pressure. These instruments benefit from the bellows’ ability to deliver reliable precision without leakage or mechanical interference.

Tunable Optics and Positioning Devices

Scientific instruments often require components to move with nanometer precision. Edge welded bellows enable such fine motion by coupling positioning devices with isolated chambers. This allows researchers to fine-tune optical alignments or sample positions without introducing vibrations or vacuum instability.

Advantages Over Other Bellows Types

Compact Design and Higher Stroke Length

Compared to formed bellows or hydraulically expanded bellows, edge welded bellows can offer greater stroke in a smaller volume. This makes them especially useful in space-constrained setups where flexibility cannot be sacrificed. Their modular diaphragm construction enables custom stroke lengths tailored to each application.

Enhanced Control and Repeatability

Precision is not only about movement but also about control and repeatability. Edge welded bellows exhibit minimal hysteresis and low spring rates, ensuring consistent performance cycle after cycle. In automated or feedback-controlled systems, this translates to better process reliability and reduced maintenance.

Design Considerations for Optimal Performance

Material and Weld Quality

The choice of material and the quality of edge welding directly affect the performance of the bellows. High-purity stainless steel is typically used for vacuum applications due to its excellent mechanical and thermal characteristics. Welding techniques must be flawless to ensure uniform strength and vacuum integrity across all diaphragms.

Geometric Flexibility and Fatigue Life

Engineers must also consider geometric design — including convolution height, pitch, and number of plies — to tailor the bellows for specific motion profiles and life cycles. A well-designed edge welded bellows unit can withstand millions of cycles in a high-vacuum environment without losing elasticity or sealing capacity.

Emerging Trends in Edge Welded Bellows Technology

Miniaturization and Microfabrication

With the miniaturization of devices and instruments, demand is rising for micro-scale edge welded bellows. Microfabricated bellows are now being explored for integration into MEMS devices and microfluidic systems. These innovations will push the boundaries of what is possible in compact vacuum systems.

Additive Manufacturing and New Alloys

The rise of additive manufacturing (3D printing) offers potential for producing complex bellows shapes with reduced lead time and cost. Combined with the development of new high-performance alloys, this trend could enable edge welded bellows to perform in even more extreme or exotic environments.

Frequently Asked Questions

What materials are best suited for edge welded bellows in vacuum applications?

Stainless steel is the most common due to its strength, weldability, and corrosion resistance. Inconel and Hastelloy are also used in more demanding environments.

How long can edge welded bellows last in a vacuum system?

With proper design and usage, edge welded bellows can last for millions of cycles without losing vacuum integrity or mechanical flexibility.

Are edge welded bellows suitable for cleanroom use?

Yes, they generate minimal particles and can be cleaned to high standards, making them ideal for cleanroom and semiconductor environments.

Can edge welded bellows be customized for different motion requirements?

Absolutely. Their modular diaphragm design allows for custom stroke lengths, diameters, and motion profiles tailored to specific applications.

Table of Contents

- Precision Flexibility in Vacuum Environments

- Versatility in Vacuum Transfer Systems

- Enabling High Vacuum and Ultra-High Vacuum Conditions

- Integration in Semiconductor Manufacturing

- Application in Analytical Instruments

- Advantages Over Other Bellows Types

- Design Considerations for Optimal Performance

- Emerging Trends in Edge Welded Bellows Technology

- Frequently Asked Questions