Understanding System Demands for Bellows Design

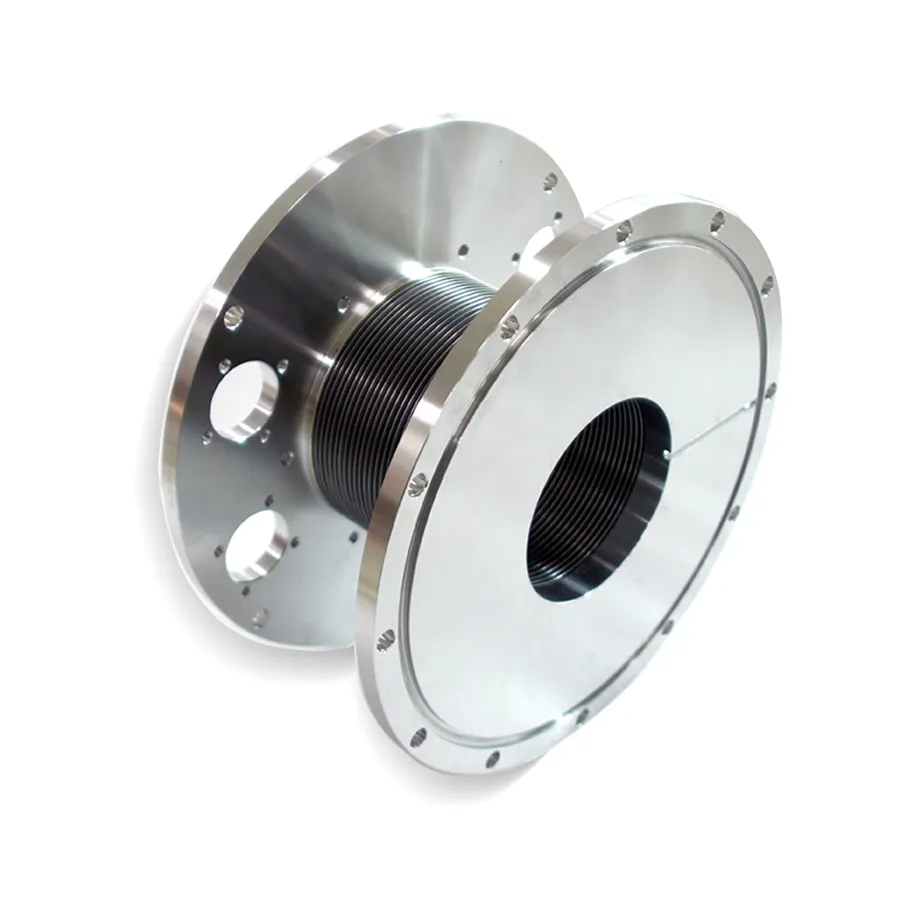

Choosing the right component for your vacuum, semiconductor, aerospace, or industrial system begins with understanding your specific operational environment. When it comes to selecting an Edge Welded Bellow, the nature of your application will heavily dictate the materials, dimensions, and configuration required. Edge Welded Bellows are highly engineered components that offer flexibility, pressure containment, and hermetic sealing—all vital features for demanding environments.

These bellows are often used in ultra-high vacuum and pressure systems due to their ability to manage mechanical movement while maintaining system integrity. Therefore, when determining the right Edge Welded Bellow for your system, consider all factors including load types, motion profiles, compatibility, and lifecycle expectations.

Key Design Considerations for Selection

Axial, Lateral, and Angular Movement Requirements

Edge Welded Bellows are used to absorb different types of movement within a system. Understanding how much axial (compression/extension), lateral (side-to-side), and angular (bending) movement your system requires is critical. The bellow must flex without fatigue or failure across its operational life. For systems with high dynamic motion, the design must prioritize optimized convolution geometry.

Pressure and Temperature Specifications

Operating conditions in vacuum and pressure environments can be extreme. The selected Edge Welded Bellow must withstand the expected internal or external pressure levels, as well as temperature cycles. Material choice and weld quality directly impact the pressure rating and thermal stability of the component.

Material Choices and Their Implications

Common Alloys for Edge Welded Bellows

Materials such as AM350, Hastelloy, Inconel, and Titanium are frequently used for Edge Welded Bellows. Each has unique mechanical, chemical, and thermal properties. Stainless steel offers a cost-effective balance of strength and corrosion resistance, while more exotic alloys may be used for harsh or corrosive environments.

Matching Material to Application Demands

Material selection should align with the environmental and mechanical demands of the system. For high-purity applications, such as semiconductor processing, corrosion-resistant materials are a must. The wrong material can result in outgassing, mechanical failure, or poor service life, which is why it's vital to align material performance with operational needs.

Customization and Design Flexibility

Configuring for Compact Spaces

Some systems have strict spatial constraints, necessitating a compact yet highly functional bellows design. Edge Welded Bellows are ideal for these scenarios because they can be engineered with a small envelope while still delivering significant stroke and flexibility.

Integration with Other System Components

Whether connecting to flanges, valves, or fittings, Edge Welded Bellows can be designed with custom end fittings and hardware. This allows for seamless integration into your existing system without requiring extensive re-engineering or adapter components.

Performance Optimization and Longevity

Fatigue Life and Cycle Testing

Fatigue life is a major performance parameter for any Edge Welded Bellow. Bellows must be tested to ensure they can handle millions of cycles without failure. Engineers use finite element analysis and physical fatigue testing to validate bellows for long-term use, especially in mission-critical environments.

Cleanliness and Outgassing Performance

In ultra-high vacuum systems, cleanliness is paramount. Edge Welded Bellows are typically cleaned and packaged in cleanroom environments to minimize contamination and outgassing. Choosing a bellow that meets your system’s cleanliness standards ensures better performance and reliability.

Manufacturing Quality and Standards

Importance of Precise Welding Techniques

The performance of Edge Welded Bellows is highly dependent on the precision of the welds. Poor welding can lead to leaks, weak points, and early failure. Advanced laser welding techniques and stringent quality control standards are critical in producing high-performance bellows.

Compliance with Industry Certifications

Always select Edge Welded Bellows manufactured to meet or exceed industry standards such as ISO, ASME, or ASTM. Compliance ensures that the product has undergone rigorous testing and is suitable for industrial or scientific use. Certification also facilitates easier documentation for regulated industries.

Selecting the Right Supplier Partner

Experience and Engineering Support

Choosing a supplier with extensive experience in Edge Welded Bellow manufacturing is essential. Engineering support can significantly ease the design and integration process. A knowledgeable team can offer insights into material selection, stress analysis, and lifecycle optimization.

Prototyping and Fast Turnaround

When time-to-market is a factor, working with a manufacturer that offers rapid prototyping can be a competitive advantage. A quick design-to-delivery cycle helps your team iterate efficiently and validate the bellow design under real-world conditions without delay.

Cost Considerations and Value Optimization

Balancing Performance with Budget

While it may be tempting to reduce costs by choosing off-the-shelf components, they may not meet your long-term system needs. Investing in a custom Edge Welded Bellow may result in a higher initial cost but pays off through increased reliability and reduced maintenance.

Lifecycle Cost Savings

Edge Welded Bellows with high fatigue resistance, optimal materials, and precision welds tend to last longer, reducing replacement frequency. Over the life of your system, the total cost of ownership is often lower for a high-quality bellow.

Frequently Asked Questions

What materials are best for Edge Welded Bellows in corrosive environments?

Inconel and Hastelloy are among the best materials for highly corrosive environments due to their excellent resistance to chemicals and high temperatures.

How do I determine the right size and stroke length for my Edge Welded Bellow?

Engineers should assess the system’s movement requirements—axial, lateral, and angular—and select a bellow that accommodates these with a sufficient safety margin.

Can Edge Welded Bellows be cleaned for UHV applications?

Yes, many Edge Welded Bellows are manufactured in cleanroom environments and cleaned to UHV standards, making them suitable for ultra-high vacuum use.

What is the typical fatigue life of an Edge Welded Bellow?

Depending on design and application, fatigue life can range from hundreds of thousands to millions of cycles. High-quality materials and precise design can significantly extend this lifespan.

Table of Contents

- Understanding System Demands for Bellows Design

- Key Design Considerations for Selection

- Material Choices and Their Implications

- Customization and Design Flexibility

- Performance Optimization and Longevity

- Manufacturing Quality and Standards

- Selecting the Right Supplier Partner

- Cost Considerations and Value Optimization

- Frequently Asked Questions