Selecting an appropriate vacuum chamber represents a critical decision that directly impacts the success of your scientific research, industrial processes, or manufacturing operations. The complexity of modern applications demands careful consideration of multiple technical factors, from chamber geometry and material compatibility to pumping system integration and operational requirements. Understanding these fundamental aspects ensures optimal performance, longevity, and cost-effectiveness of your vacuum system investment.

Understanding Vacuum Chamber Fundamentals

Core Design Principles

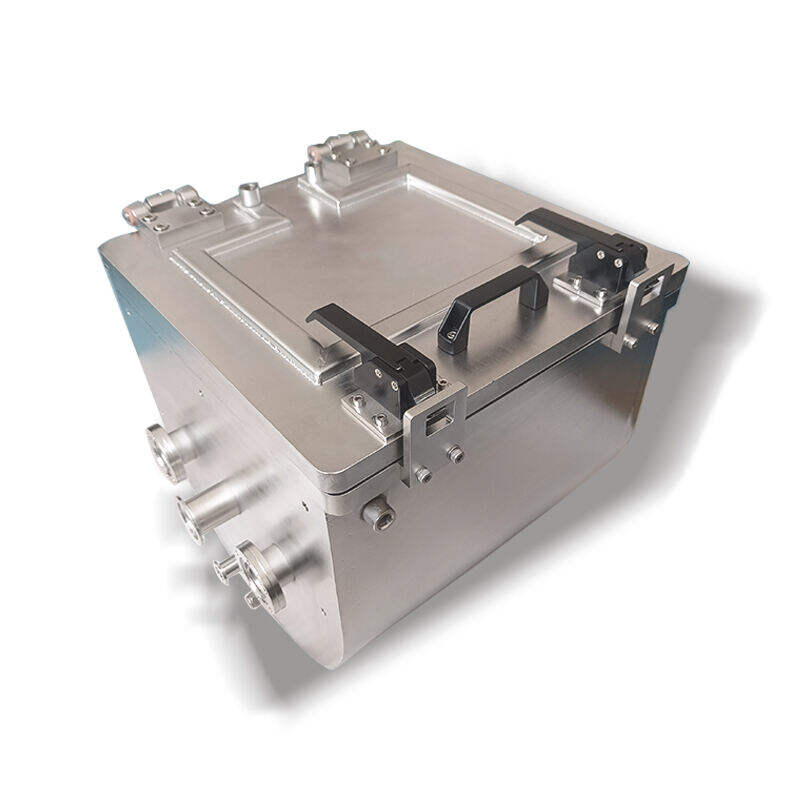

The fundamental design of a vacuum chamber revolves around creating and maintaining controlled low-pressure environments for various applications. Modern vacuum chambers incorporate sophisticated engineering principles that balance structural integrity with operational flexibility. The chamber walls must withstand atmospheric pressure differential while providing necessary ports for process connections, monitoring equipment, and pumping systems. Material selection plays a crucial role in determining the ultimate vacuum level achievable and the chamber's compatibility with specific processes.

Chamber geometry significantly influences pumping efficiency and process uniformity. Cylindrical designs offer excellent structural strength and uniform stress distribution, making them ideal for high-vacuum applications. Rectangular chambers provide better accessibility and accommodate larger substrates but require additional reinforcement. The internal surface finish directly affects outgassing rates and achievable vacuum levels, with electropolished stainless steel surfaces delivering superior performance for ultra-high vacuum applications.

Pressure Range Considerations

Different applications require specific pressure ranges, and your vacuum chamber selection must align with these requirements. Rough vacuum applications typically operate between atmospheric pressure and 1 Torr, suitable for basic degassing and simple material processing. High vacuum ranges from 10^-3 to 10^-9 Torr accommodate most research and industrial applications, including thin film deposition and surface analysis. Ultra-high vacuum conditions below 10^-9 Torr demand specialized chamber designs with minimal outgassing materials and advanced sealing technologies.

The pumping system configuration directly correlates with the intended pressure range and chamber volume. Mechanical pumps handle initial evacuation and rough vacuum maintenance, while turbomolecular pumps achieve high vacuum conditions. Ion pumps and getter pumps maintain ultra-high vacuum environments for extended periods. Your vacuum chamber must accommodate the appropriate pumping ports and support the required pumping speed to achieve target pressures within acceptable timeframes.

Material Selection and Construction Quality

Stainless Steel Specifications

Stainless steel remains the preferred material for most vacuum chamber applications due to its excellent mechanical properties, corrosion resistance, and low outgassing characteristics. Type 304 stainless steel offers good performance for general applications, while Type 316L provides superior corrosion resistance and lower magnetic permeability for sensitive applications. The material's surface finish significantly impacts vacuum performance, with electropolished surfaces reducing outgassing rates by orders of magnitude compared to standard mill finishes.

Wall thickness calculations must account for atmospheric pressure loads, safety factors, and operational stresses. Standard atmospheric pressure exerts approximately 14.7 pounds per square inch on chamber walls, requiring adequate structural design to prevent deformation. Thicker walls provide better structural integrity but increase thermal mass and complicate heating applications. Advanced finite element analysis helps optimize wall thickness while maintaining structural safety margins and operational flexibility.

Alternative Materials and Coatings

Specialized applications may require alternative materials or surface treatments to achieve specific performance characteristics. Aluminum chambers offer reduced weight and excellent thermal conductivity but require careful surface treatment to minimize outgassing. Glass chambers provide optical access and chemical inertness but limit achievable vacuum levels and structural loading capabilities. Ceramic-coated surfaces eliminate metallic contamination in sensitive processes while maintaining structural integrity of the base material.

Surface treatments enhance vacuum chamber performance for specific applications. Electroless nickel plating provides uniform surface properties and improved corrosion resistance. Passivation treatments optimize stainless steel surfaces for maximum vacuum performance. Specialized coatings can provide non-stick properties, enhanced thermal conductivity, or specific chemical compatibility depending on process requirements. The selection of surface treatments must balance performance benefits with cost considerations and long-term maintenance requirements.

Size and Configuration Optimization

Volume and Geometry Calculations

Determining the appropriate vacuum chamber volume requires careful analysis of process requirements, substrate sizes, and equipment integration needs. Larger chambers accommodate bigger workpieces and multiple samples but require more powerful pumping systems and longer pumpdown times. The chamber-to-pumping-speed ratio directly affects evacuation time and ultimate pressure capabilities. Process gases and vapor loads must be factored into volume calculations to ensure adequate pumping capacity for maintaining target pressures during operation.

Chamber geometry affects gas flow patterns and pumping efficiency throughout the evacuation process. Dead volumes and sharp corners can trap gases and create virtual leaks that compromise vacuum performance. Smooth transitions and adequate conductance paths ensure uniform pressure distribution and efficient gas removal. The positioning of pumping ports relative to gas sources and chamber geometry significantly influences overall system performance and process uniformity.

Access and Port Configuration

Port selection and placement determine the flexibility and functionality of your vacuum chamber system. Standard conflat flanges provide reliable ultra-high vacuum seals and accommodate various feedthrough options. The number and size of ports must accommodate current needs while providing expansion capability for future requirements. Electrical feedthroughs enable power delivery and signal transmission into the vacuum environment, while mechanical feedthroughs allow manipulation of samples and equipment.

Optical windows expand analytical capabilities by enabling real-time process monitoring and laser-based techniques. Window materials must be compatible with the wavelength range of interest while maintaining vacuum integrity. Heated ports prevent condensation of process vapors and maintain seal reliability in challenging environments. The strategic placement of ports optimizes accessibility while maintaining structural integrity and vacuum performance of the overall system.

Application-Specific Requirements

Research and Development Applications

Research environments demand maximum flexibility and analytical capabilities from vacuum chamber systems. Multi-port configurations accommodate diverse experimental setups and enable simultaneous use of multiple analytical techniques. Temperature control capabilities extend the range of possible experiments and enable thermal cycling studies. The chamber design must accommodate sample holders, heating elements, and various analytical probes while maintaining excellent vacuum performance and contamination control.

Academic and industrial research applications often require custom chamber configurations to meet specific experimental needs. Modular designs enable reconfiguration for different experiments while maintaining cost-effectiveness. Advanced materials compatibility ensures the chamber can handle corrosive gases, reactive materials, and high-temperature processes. Documentation and traceability requirements in research environments necessitate comprehensive material certifications and quality control records.

Industrial Manufacturing Processes

Manufacturing applications prioritize reliability, throughput, and consistent performance over maximum flexibility. Automated loading systems reduce cycle times and minimize contamination from manual handling. Robust construction withstands continuous operation and frequent thermal cycling associated with production environments. The vacuum chamber design must integrate seamlessly with existing production equipment and meet stringent quality control requirements for manufactured products.

Process repeatability and contamination control become critical factors in manufacturing applications. Standardized chamber designs ensure consistent performance across multiple production lines. Advanced cleaning protocols and surface treatments minimize particle generation and maintain product quality. The chamber system must accommodate high-volume processing while maintaining the precision and control required for modern manufacturing standards.

Integration with Pumping Systems

Pumping Speed Requirements

Calculating appropriate pumping speed requirements involves analyzing gas loads, desired evacuation times, and ultimate pressure targets. The effective pumping speed at the chamber depends on pump specifications and conductance limitations of connecting lines. Molecular flow conditions in high vacuum systems require careful consideration of conductance calculations to optimize pump placement and sizing. Process gas loads during operation may exceed base vacuum requirements and necessitate additional pumping capacity.

Pump selection affects both initial investment costs and long-term operational expenses. Mechanical pumps provide high throughput for rough evacuation but require regular maintenance and oil changes. Turbomolecular pumps achieve excellent high vacuum performance with minimal maintenance requirements. Scroll pumps offer oil-free operation for applications requiring clean environments. The pumping system configuration must balance performance requirements with operational costs and maintenance considerations.

Pump Integration Design

Proper integration of pumping systems with the vacuum chamber ensures optimal performance and reliability. Pump port sizing must provide adequate conductance while maintaining structural integrity of the chamber walls. Isolation valves enable pump maintenance without breaking chamber vacuum and protect sensitive processes from pump-related disturbances. Foreline traps prevent backstreaming of pump fluids into the high vacuum environment and protect process integrity.

Control system integration enables automated pump sequencing and system protection. Interlocked safety systems prevent damage from improper operating sequences and protect personnel from hazardous conditions. Remote monitoring capabilities provide real-time system status and enable predictive maintenance programs. The integration design must accommodate future system upgrades and modifications while maintaining reliable operation throughout the system lifecycle.

Environmental and Safety Considerations

Temperature Control Capabilities

Temperature control requirements significantly influence vacuum chamber design and material selection. Heating systems must provide uniform temperature distribution while maintaining vacuum integrity and safety standards. Resistive heating elements integrated into chamber walls offer excellent temperature uniformity but complicate chamber construction. External heating jackets provide flexibility but may create temperature gradients and increase thermal mass. Cooling capabilities enable rapid temperature cycling and protect sensitive components from thermal damage.

Thermal expansion considerations become critical in precision applications and extended temperature ranges. Differential expansion between chamber components can compromise seal integrity and dimensional stability. Flexible connections and expansion joints accommodate thermal movement while maintaining vacuum performance. Thermal modeling helps predict system behavior and optimize design for specific temperature requirements and operational profiles.

Safety and Compliance Standards

Safety considerations encompass both personnel protection and equipment reliability in vacuum chamber applications. Implosion protection prevents catastrophic failure under atmospheric pressure loading and protects nearby personnel and equipment. Emergency venting systems enable rapid chamber pressurization in emergency situations while controlling the rate of pressure change. Electrical safety systems prevent shock hazards from high-voltage feedthroughs and heating elements operating in vacuum environments.

Regulatory compliance varies by industry and application but generally includes pressure vessel codes, electrical safety standards, and environmental regulations. Documentation requirements include material certifications, pressure testing records, and quality control documentation. International standards such as ISO and ASME provide guidelines for design, construction, and testing of vacuum systems. Compliance with these standards ensures safe operation and facilitates equipment acceptance in various markets and applications.

FAQ

What factors determine the ultimate vacuum level achievable in a vacuum chamber

The ultimate vacuum level depends on several interconnected factors including chamber materials, surface treatments, seal quality, and pumping system capabilities. Outgassing from chamber walls and internal components typically limits achievable pressures more than pump specifications. Electropolished stainless steel surfaces with minimal weld joints achieve the lowest outgassing rates. Proper leak detection and seal maintenance ensure the chamber envelope maintains its integrity over time.

How do I calculate the required pumping speed for my vacuum chamber application

Pumping speed calculations must account for chamber volume, desired evacuation time, gas loads during operation, and conductance limitations. The basic formula relates pumping speed to gas load and desired pressure, but practical systems require consideration of molecular flow conditions and pump-down curves. Process-specific gas loads often exceed base vacuum requirements and may necessitate significantly larger pumping systems than initial calculations suggest.

What maintenance requirements should I expect for different vacuum chamber materials and configurations

Stainless steel chambers require periodic cleaning and seal replacement but generally offer long service life with minimal maintenance. Surface treatments may require refresh cycles depending on process conditions and contamination levels. Pumping systems typically require more frequent maintenance than the chamber itself, with mechanical pumps needing oil changes and turbomolecular pumps requiring bearing replacement. Establishing preventive maintenance schedules based on operational hours and performance monitoring helps optimize system reliability and minimize unexpected downtime.

How important is chamber volume versus pumping speed in achieving target pressures quickly

The relationship between chamber volume and pumping speed directly affects evacuation time through exponential pump-down curves. Smaller chambers reach target pressures faster with given pumping systems, but may limit process flexibility and sample sizes. Effective pumping speed at the chamber location may be significantly lower than pump ratings due to conductance limitations. Optimizing the balance between chamber size and pumping capacity requires careful analysis of specific application requirements and cost considerations.

Table of Contents

- Understanding Vacuum Chamber Fundamentals

- Material Selection and Construction Quality

- Size and Configuration Optimization

- Application-Specific Requirements

- Integration with Pumping Systems

- Environmental and Safety Considerations

-

FAQ

- What factors determine the ultimate vacuum level achievable in a vacuum chamber

- How do I calculate the required pumping speed for my vacuum chamber application

- What maintenance requirements should I expect for different vacuum chamber materials and configurations

- How important is chamber volume versus pumping speed in achieving target pressures quickly