High-vacuum applications demand precision-engineered components that can maintain ultra-low pressure environments while ensuring reliable operation. Among the most critical components in vacuum systems, the vacuum gate valve serves as a fundamental control element that determines system performance and operational efficiency. Understanding the characteristics and selection criteria for these specialized valves is essential for engineers and technicians working in semiconductor manufacturing, research laboratories, and industrial vacuum processing environments.

The selection of an appropriate vacuum gate valve directly impacts system integrity, pumping efficiency, and overall process reliability. Different valve designs offer varying levels of leak tightness, operational convenience, and compatibility with specific process requirements. Modern vacuum technology has evolved to support increasingly demanding applications, from ultra-high vacuum research to complex multi-chamber processing systems used in advanced manufacturing.

Understanding Vacuum Gate Valve Fundamentals

Basic Operating Principles

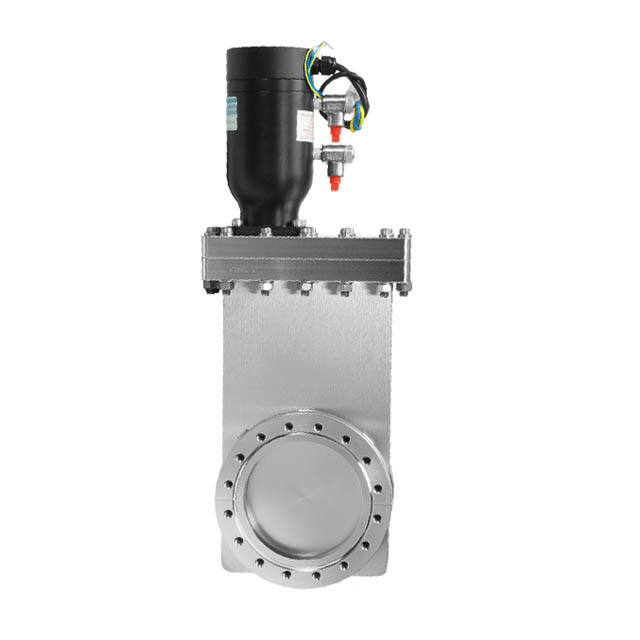

A vacuum gate valve operates by moving a flat gate or disc perpendicular to the flow path, creating a complete seal when closed. This linear motion design provides several advantages over rotary valve types, including zero dead volume when open and excellent sealing characteristics when properly maintained. The gate mechanism typically moves through a threaded shaft system or pneumatic actuator, depending on the specific application requirements and automation needs.

The sealing mechanism relies on either metal-to-metal contact or elastomeric seals, with each approach offering distinct performance characteristics. Metal-sealed designs provide superior chemical compatibility and temperature resistance, while elastomer-sealed versions offer enhanced leak tightness at lower operating costs. Understanding these fundamental differences helps engineers select the most appropriate valve type for their specific vacuum application.

Critical Performance Parameters

Several key performance metrics define the suitability of a vacuum gate valve for high-vacuum applications. Leak rate specifications, typically measured in standard cubic centimeters per second (scc/s), determine the valve's ability to maintain system vacuum levels. Ultra-high vacuum applications may require leak rates below 10^-9 scc/s, while industrial applications might accept higher leak rates for improved cost-effectiveness.

Conductance values indicate the valve's flow characteristics when fully open, affecting pumping speed and system evacuation time. Higher conductance values generally improve system performance, but must be balanced against mechanical design constraints and sealing requirements. Operating temperature range, chemical compatibility, and cycle life also significantly influence valve selection decisions in demanding high-vacuum environments.

Types of Vacuum Gate Valves for High-Vacuum Service

Manual Gate Valves

Manual vacuum gate valves provide reliable, cost-effective isolation for systems that require infrequent operation or where automated control is unnecessary. These valves feature hand-operated mechanisms that allow precise control over gate position and closing force. The manual operation eliminates potential failure modes associated with pneumatic or electric actuators, making them ideal for critical isolation applications where reliability takes precedence over convenience.

The design simplicity of manual valves often results in superior leak tightness and longer service life compared to automated alternatives. Many high-vacuum systems incorporate manual gate valves as primary isolation devices, particularly in applications where valve operation occurs during maintenance procedures rather than routine process cycles. The vacuum gate valve with manual operation provides excellent reliability for demanding applications.

Pneumatic Gate Valves

Pneumatic vacuum gate valves offer automated operation suitable for process control and remote operation requirements. These valves incorporate compressed air actuators that provide rapid opening and closing cycles, essential for applications requiring frequent valve operation or integration with automated control systems. The pneumatic design enables remote operation from control rooms, improving operator safety and system accessibility.

Modern pneumatic gate valves feature position indication systems and fail-safe mechanisms that ensure predictable behavior during power failures or air supply interruptions. Some designs incorporate spring-return actuators that automatically close or open the valve when air pressure is lost, providing enhanced process safety. The response time and operating force of pneumatic actuators can be adjusted to match specific application requirements, from gentle closing for delicate processes to rapid cycling for high-throughput systems.

Bellows-Sealed Gate Valves

Bellows-sealed vacuum gate valves represent the premium solution for ultra-high vacuum applications requiring exceptional leak tightness and contamination control. The metal bellows provides a hermetic seal around the valve stem, eliminating potential leak paths through dynamic seals or packing arrangements. This design ensures that the vacuum chamber remains isolated from atmospheric contamination, even during valve operation.

The bellows mechanism also provides inherent compensation for thermal expansion and mechanical tolerances, maintaining consistent sealing performance across wide temperature ranges. Stainless steel bellows construction offers excellent chemical resistance and durability, while specialized alloys can provide enhanced performance in corrosive environments or extreme temperature conditions. The bellows design requires careful consideration of cycle life limitations and proper installation procedures to ensure optimal performance.

Selection Criteria for High-Vacuum Applications

Vacuum Level Requirements

The ultimate vacuum level required by the application serves as the primary selection criterion for vacuum gate valves. Ultra-high vacuum systems operating below 10^-9 Torr typically require bellows-sealed valves with all-metal sealing surfaces to achieve the necessary leak tightness. These applications often involve research instruments, surface analysis equipment, or specialized manufacturing processes where even minimal contamination can compromise results.

High-vacuum systems operating in the 10^-6 to 10^-9 Torr range may utilize either bellows-sealed or elastomer-sealed valves, depending on specific contamination sensitivity and operational requirements. Industrial vacuum processing applications often operate in this range, where the balance between performance and cost becomes critical. Standard vacuum applications above 10^-6 Torr can typically use conventional elastomer-sealed valves with appropriate material selection.

Process Compatibility Considerations

Chemical compatibility between valve materials and process gases or vapors significantly influences valve selection decisions. Corrosive gases may require specialized seal materials or all-metal construction to prevent degradation and maintain long-term reliability. Stainless steel construction provides excellent compatibility with most industrial processes, while specialized alloys like Hastelloy or Inconel may be necessary for highly corrosive environments.

Temperature cycling and extreme operating temperatures also affect material selection and valve design. High-temperature applications may require metal-sealed valves or specialized elastomer compounds that maintain flexibility and sealing properties at elevated temperatures. Cryogenic applications present unique challenges related to material brittleness and thermal contraction, requiring careful attention to material selection and mechanical design details.

Operational Requirements

The frequency and method of valve operation significantly influence the appropriate valve type selection. Applications requiring frequent cycling favor pneumatic or motorized actuation to reduce operator workload and ensure consistent operation. Manual valves remain suitable for applications where operation occurs primarily during maintenance or setup procedures, offering superior reliability and lower initial cost.

Integration with control systems and safety interlocks may require valves with position feedback, remote operation capability, and fail-safe operation modes. Pneumatic valves can be equipped with solenoid pilot valves for electrical control integration, while manual valves may incorporate limit switches or position indicators for monitoring purposes. The choice between these options depends on the overall system complexity and automation requirements.

Installation and Maintenance Best Practices

Proper Installation Procedures

Correct installation procedures are critical for achieving optimal performance from vacuum gate valves in high-vacuum applications. Flange connections must be properly aligned and torqued according to manufacturer specifications to ensure uniform sealing force distribution. The use of appropriate gaskets or sealing rings, matched to the specific flange standard and application requirements, prevents leak paths that could compromise system performance.

Valve orientation considerations include ensuring that the gate mechanism operates smoothly without binding or interference from adjacent components. Pneumatic valves require proper air supply connections with appropriate filtration and pressure regulation to ensure reliable operation. The installation environment should provide adequate access for maintenance procedures while protecting the valve from mechanical damage or contamination sources.

Maintenance and Troubleshooting

Regular maintenance schedules help ensure continued performance and extend service life of vacuum gate valves. Leak testing procedures should be performed periodically using helium leak detectors or other appropriate methods to verify sealing integrity. Preventive maintenance may include lubrication of moving parts, inspection of sealing surfaces, and replacement of wear components according to manufacturer recommendations.

Common troubleshooting issues include gradual leak rate increases, mechanical binding, or actuator malfunctions. Systematic diagnostic procedures can isolate problems to specific valve components, enabling targeted repairs or component replacement. Maintaining spare parts inventory for critical valves ensures minimal downtime during maintenance procedures, particularly important for production systems where vacuum integrity is essential for product quality.

Emerging Technologies and Future Developments

Advanced Materials and Coatings

Recent developments in materials science have produced new options for vacuum gate valve construction that offer enhanced performance characteristics. Advanced coating technologies provide improved surface hardness, chemical resistance, and reduced outgassing properties compared to conventional materials. These coatings can extend service life and improve compatibility with aggressive process chemistries while maintaining excellent vacuum performance.

Nanostructured surface treatments and specialized alloy compositions continue to push the boundaries of what is possible in high-vacuum applications. These technologies enable valves to operate reliably in increasingly demanding environments while providing improved cost-effectiveness through extended service life and reduced maintenance requirements.

Smart Valve Technologies

Integration of intelligent monitoring and control systems represents a significant advancement in vacuum gate valve technology. Smart valves incorporate sensors that continuously monitor operating parameters such as position, sealing force, and leak rates, providing real-time feedback to system operators. This data enables predictive maintenance strategies that can prevent unexpected failures and optimize maintenance scheduling.

Wireless communication capabilities and integration with industrial internet of things (IIoT) platforms allow remote monitoring and control of valve systems from centralized control facilities. These capabilities are particularly valuable for large vacuum systems or installations in hazardous environments where minimizing operator exposure is important for safety and operational efficiency.

FAQ

What is the difference between bellows-sealed and elastomer-sealed vacuum gate valves

Bellows-sealed vacuum gate valves use a metal bellows to provide hermetic sealing around the valve stem, eliminating any dynamic seals that could leak. This design achieves superior leak tightness, typically below 10^-9 scc/s, making them ideal for ultra-high vacuum applications. Elastomer-sealed valves use O-rings or other rubber seals, which are more cost-effective but generally achieve leak rates in the 10^-6 to 10^-8 scc/s range, suitable for many industrial high-vacuum applications.

How do I determine the appropriate conductance value for my vacuum system

Conductance requirements depend on your system's pumping speed needs and acceptable evacuation time. Generally, valve conductance should be at least 2-3 times higher than your pump's effective pumping speed to avoid significant flow restriction. For critical applications, conductance values 5-10 times the pump speed may be necessary. Consider the valve's conductance in relation to other system components like connecting pipes and chambers to optimize overall system performance.

What maintenance schedule should I follow for vacuum gate valves

Maintenance frequency depends on operating conditions and valve type. For critical applications, perform leak testing monthly or quarterly using helium leak detectors. Visual inspection of sealing surfaces and moving parts should occur during each system maintenance cycle. Bellows-sealed valves typically require less frequent maintenance than elastomer-sealed types, but monitor cycle counts if your application involves frequent operation. Replace elastomeric seals according to manufacturer recommendations or when leak rates exceed acceptable limits.

Can vacuum gate valves be repaired in the field or must they be returned to the manufacturer

Many vacuum gate valve repairs can be performed in the field with proper tools and spare parts. Simple maintenance like O-ring replacement, actuator adjustment, or cleaning can typically be done on-site. However, bellows repair or replacement, precision machining of sealing surfaces, or complex actuator rebuilds usually require factory service or specialized repair facilities. Maintain appropriate spare parts inventory and ensure technicians receive proper training for field-repairable components to minimize downtime.

Table of Contents

- Understanding Vacuum Gate Valve Fundamentals

- Types of Vacuum Gate Valves for High-Vacuum Service

- Selection Criteria for High-Vacuum Applications

- Installation and Maintenance Best Practices

- Emerging Technologies and Future Developments

-

FAQ

- What is the difference between bellows-sealed and elastomer-sealed vacuum gate valves

- How do I determine the appropriate conductance value for my vacuum system

- What maintenance schedule should I follow for vacuum gate valves

- Can vacuum gate valves be repaired in the field or must they be returned to the manufacturer